-

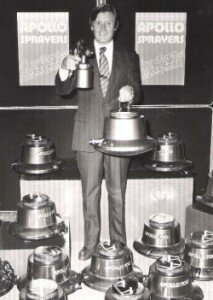

John and Apollo 700s, named for the Space Capsule

In 1984 John brilliantly submitted independent laboratory tests to SCAQMD demonstrating that Apollo’s turbine system could produce over 80 percent transfer efficiency, which meant that 80% of the coating stayed on the work surface. Far less solvent blew out into the atmosphere. SCAQMD called it High Volume Low Pressure or HVLP.

In 1984 John brilliantly submitted independent laboratory tests to SCAQMD demonstrating that Apollo’s turbine system could produce over 80 percent transfer efficiency, which meant that 80% of the coating stayed on the work surface. Far less solvent blew out into the atmosphere. SCAQMD called it High Volume Low Pressure or HVLP.Soon California required transfer efficiency to be 65% or more. Other towns and cities followed suit.

Over the years coatings became more viscous and Apollo Sprayers anticipated the changes. Turbines became more powerful. Guns became lighter and used stainless steel. More and more industries awakened to HVLP. And the competition entered the field.

Competition worked well for us. Each of our innovations was quickly copied. We took that as a form of praise, worked harder, and we are proud of our high quality machines, built in the USA and sold all over the world We export to companies in China, Egypt, India, Columbia, Russia, Israel, the Netherlands, Egypt and more.

It’s been a great time for us. So Happy 50th to us and wishing everyone Happy New Year.

Essentials for Every Woodworker, Novice or Master Woodworker

Blow Off Tool In Action

ECO5 ECO-LOGICAL, ECO-NOMICAL TURBINE SYSTEM Efficient 5 stage turbine

Painters Pyramid Effortless and "touch free"

Nour AquaGlide Plus Nylon Fine Bristle Brush

Erecta-Rack quickly and effectively dry doors and shelves